Unify OT and IT data across your plants for real-time visibility and control

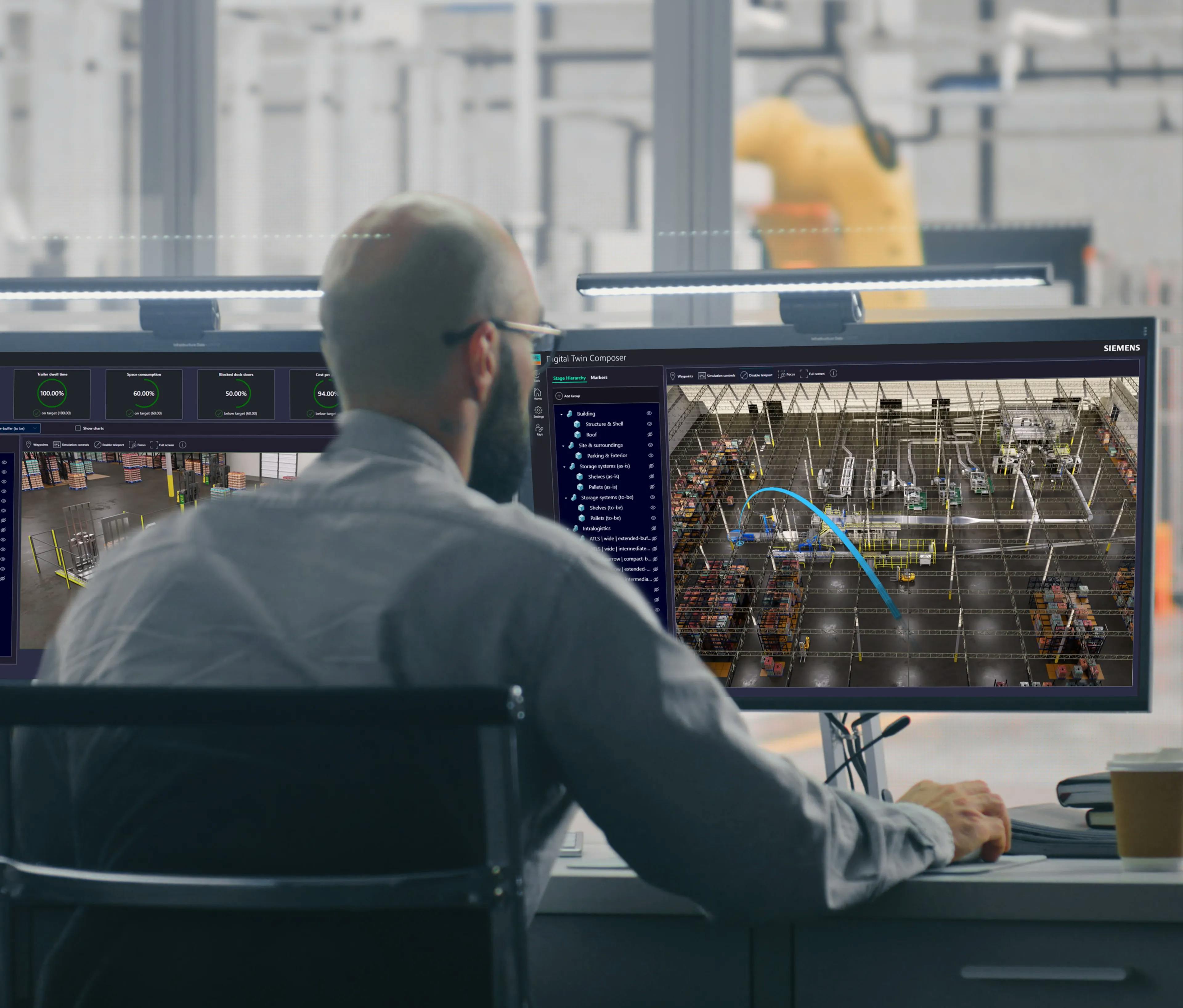

Digital Twin Composer with Siemens Xcelerator connects siloed manufacturing systems to enable closed-loop control across your multi-plant operations. Our integrated hardware-software approach reduces risk during deployment and delivers measurable results fast.

• Cut unplanned downtime by synchronizing real-time data from every line and facility

• Increase throughput with production models that continuously adapt to actual conditions

• Deploy with confidence using proven industrial controllers and software already trusted in automotive plants worldwide

Trusted by production and operations leaders

Proven results in manufacturing and multi-plant deployments

"Managing complex systems reliably across multiple facilities requires visibility and control at every level. This platform gives us that capability."

"Virtual simulation allowed us to test and validate configurations before physical implementation. This approach reduces risk and creates a repeatable model for rolling out across plants."

"Reliable operations at scale are critical when you're expanding production capacity. The system proved itself in live deployment and gave us confidence to scale further."

Questions about multi-plant manufacturing operations

Common technical questions from manufacturing leaders about protocol integration, data standards, and scaling across global plants.

Contact usHow do we handle the different equipment protocols across our plants?

Siemens Xcelerator provides pre-built connectors for common industrial protocols—OPC UA, MQTT, Modbus, and proprietary interfaces. The platform normalizes data from different sources into a consistent model. This means you can ingest signals from mixed equipment vendors without writing custom integration code for each one. Governance tools help you define standards once and apply them across sites.

Can we unify our OT and IT systems for a consistent view?

Digital Twin Composer connects operational signals from the shop floor with business context from ERP and MES. It aligns OT data models and IT metadata so you see equipment performance, production schedules, and quality metrics in one place. Reference architectures guide the setup. Role-based access ensures plant engineers and business analysts each get the view they need, near real time.

Will this scale across all our global plants with the same standards?

Yes. The platform is built for enterprise rollout. You can define templates for data models, security policies, and workflows, then replicate them to each site. Network segmentation protects operational technology. Centralized governance keeps standards consistent. Many customers start with a pilot line, validate the approach, and then expand plant by plant to reduce risk.

How do we deploy predictive maintenance across multiple plants?

Once equipment data is standardized and contextualized, you can build condition monitoring, anomaly detection, and remaining useful life models. These use cases run on the same data foundation across sites. You train models on historical failures, test them in one plant, and roll out proven algorithms to others. The result is fewer unplanned stops and better maintenance planning.

What's the best way to start a multi-plant pilot?

Our FAQ section covers the most common inquiries about our services and processes. For specific questions not addressed here, please reach out to our support team. More questions? Contact us via email or LinkedIn.

Manufacturing Intelligence

Industrial AI and Digital Twins for Smart Factories

Learn how automotive manufacturers use predictive maintenance, throughput analysis, and closed-loop production control to increase uptime, improve quality, and reduce operational costs.

Start Your Multi-Plant Pilot Today

Our integrated hardware and software solutions give you real-time visibility and control across all your plants. Improve process performance, reduce energy costs, and increase operational reliability at scale. Request a no-obligation consultation to scope a multi-plant pilot and see how we can de-risk your path to fleet-wide results.